Upload drawings immediately, get quotation within 5 minutes, we are

on standby 24 hours a day,

From equipment to team, we use our strength to ensure delivery

At GrowWayTech, our factories are fully equipped with cutting-edge tools and technology. Our team of skilled professionals operates CNC machines, powerful injection molding equipment (up to 830 tons), laser cutters, benders, welders, and modern 3D printers, ect. Our production lines are automated, ensuring efficiency and accuracy in everything we make.By managing our manufacturing in-house, we keep a close eye on quality at every step. This helps us maintain high standards, offer flexible scheduling for production, and provide affordable solutions without sacrificing quality. Direct control over these processes reduces risks and makes your supply chain more reliable.

[ machines ]

[ engineers & QA ]

[ customers ]

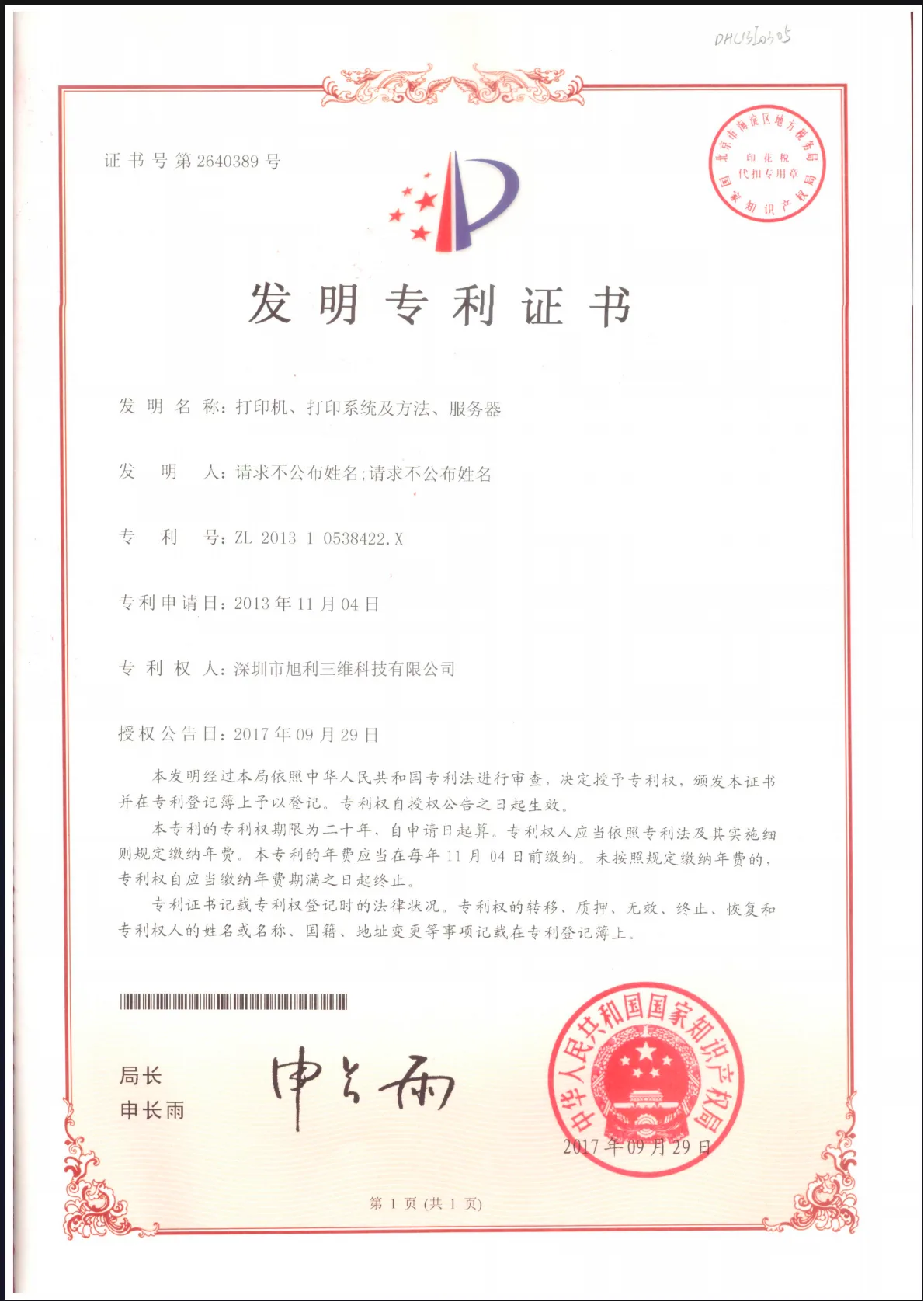

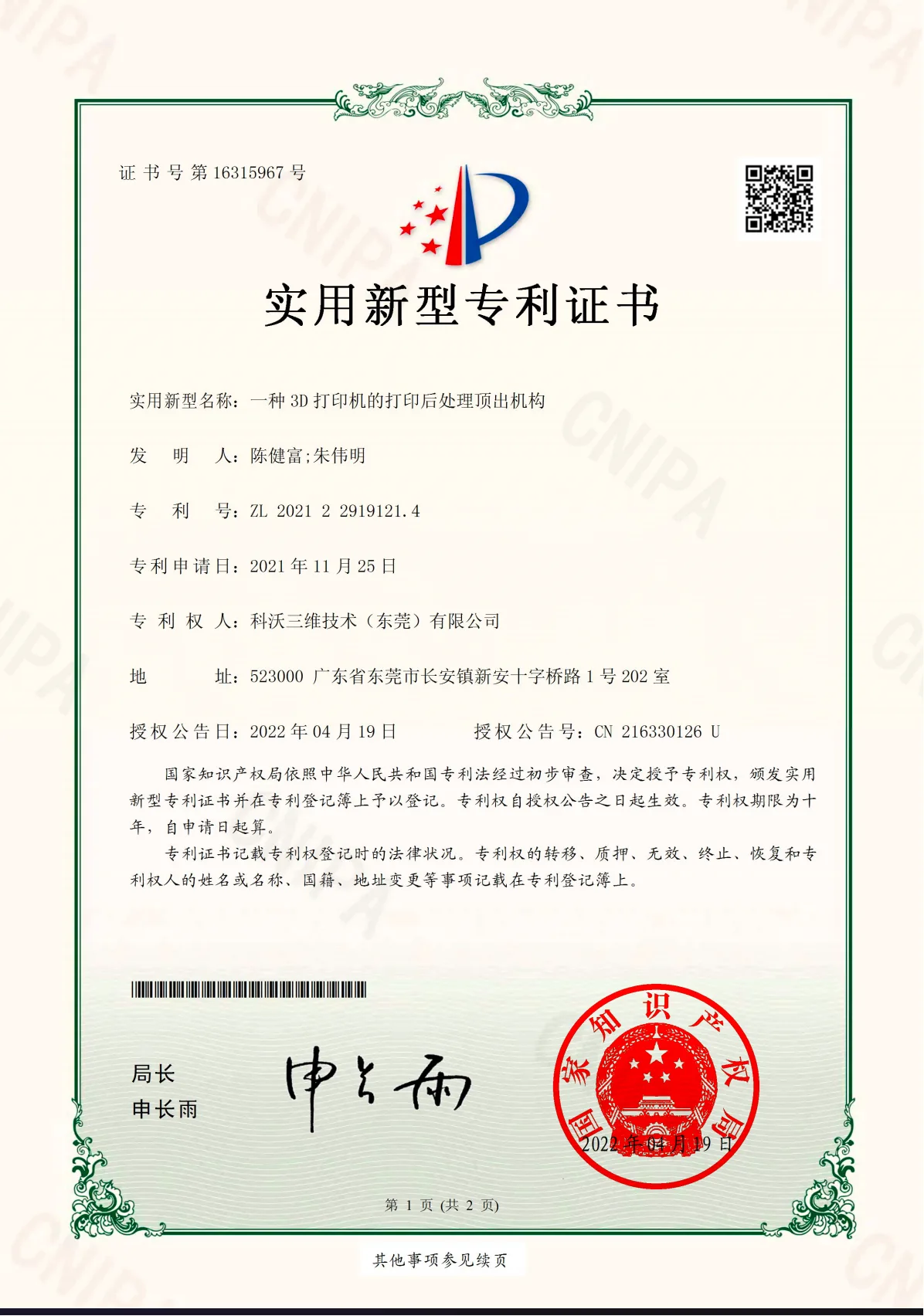

We have gone the extra mile to ensure that our operations align with the highest industry standards. To demonstrate our commitment to quality and excellence, we have proactively pursued and obtained recognized certifications from reputable organizations.

From equipment to team, we use our strength to ensure delivery

[US · Logistics Automation]“Growwaytech’s robot enclosures cut our launch time by 2 weeks—precision design + fast delivery = perfect partner.“

[Germany · Robotics Startup]“EU safety compliance + lightweight design—Growwaytech nailed our collaborative robot shell needs.”

[Thailand · Electronics Manufacturing]“Budget-friendly, high-quality shells boosted our robot durability by 30%—on-time bulk delivery was a bonus.”

Upload drawings immediately, get quotation within 5 minutes, we are on

standby 24 hours a day,

NDA/Encryption Instructions